Microwave Preheater

The conventional preheating of rubber leads to high energy losses and requires you to have significant floor space. Leading to higher costs in overall production and labour.

The use of microwave preheater reduces all such extravagant needs. It can easily perform in the range of 70 °C to 90 °C before being put inside the mold. This process is quick Since the process is quick, the material flow also increases and results in an end-product with a much better finish and higher mechanical strength.

- Increases production capacity of existing plants by 30- 40%

- Saves electricity by reducing the molding time.

- Easy to operate with electronic control boards and instant start/stop buttons.

- Enables uniform vulcanization throughout the rubber by heating the rubber from the inside out.

- Minimum floor space required and very little heat loss.

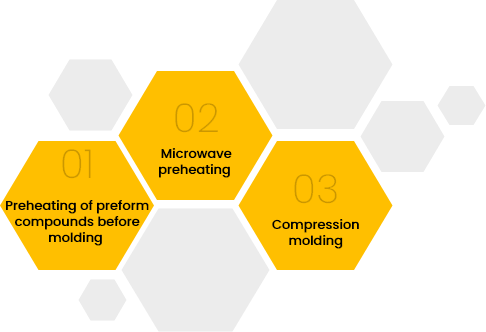

Where does it fit in your chain?

Preheating of Natural Rubber-Videos

Microwave Preheater

MICROWAVE PREHEATING SYSTEM FOR RUBBER INDUSTRY

Let the technology work for you

Save Energy, Increase Production capacity of Existing Plant by 30% to 40% by preheating rubber before molding.

“TWIN” Microwave Rubber Preheating system is cost effective solution for Rubber Idustries. Microwave is a major tool for improving quality, productivity & reduction in production cost.The technology is GREEN TECHNOLOGY. Saves fuel/electricity, time & also help to reduce environment pollutions.

Rubbers can be preheated :

| EPDM | Natural-NBR | |

| Nitrile | White EPDM | |

| Sponge Rubber | Bakelite & other Polar Thermo Plastics | & many More. |

Safety Features :

- Microwave cavity is designed for Human safety.

- Required Interlocks incorporated.

- Specially designed Microwave chokes

- Door Safety Lock.

- Microwave leakage- as per international standard of <5mW/mm2

Useful for who makes parts for below Industry :

- Agricultural Industry.

- Aerospace/ Aviation Industry.

- Automobile Industry.

- Chemical Industry.

- Construction Industry.

- Defence Industry.

| Application | Where To Implement | Advantages / USPs |

|---|---|---|

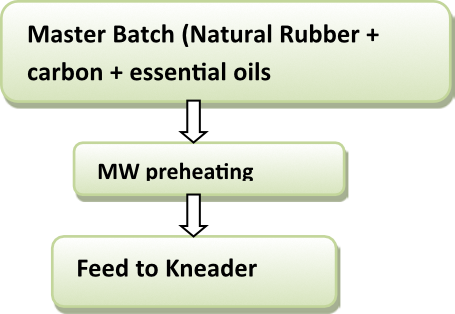

| MW preheating of Master Batch (Natural Rubber + carbon + essential oils) before Kneader |  |

|

| Application | Where To Implement | Advantages / USPs |

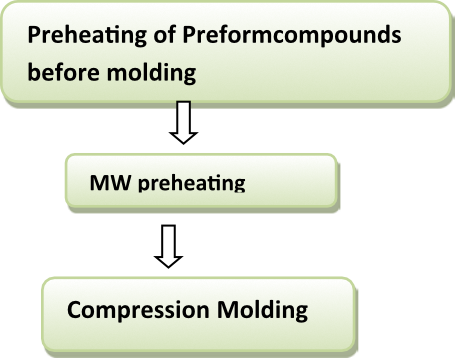

| Mw – Preheating of Preformcompounds before molding. |  |

|

| Application | Where To Implement | Advantages / USPs |

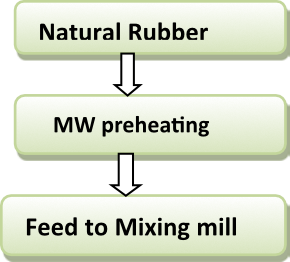

| MW preheating of Natural Rubber Bale |  |

|

| Mw preheating of compound before hot feed Extrusion |  |

|

*Trials & technical support for microwaveable compounding can be provided at our factory through our association for people who have interested.

| Standard Models : MW-preheating of NaturalRubber Bale / Master Batch Conveyerised | ||||

| Model No: | TW/MWPH/6K/CON | TW/MWPH/9K/CON | TW/MWPH/12K/CON | TW/MWPH/16K/CON |

| Production capacity kg /Hr. (approx.) | 80-100 kg/Hrs. | 120-140 kg/Hr. | 170-200 kg/Hr. | 240-260 kg/Hr. |

| Frequency | 2.45 GHz | |||

| Installed Microwave Power requirements | 6 KW | 9 KW | 12 KW | 16 KW |

| Installed electrical power | 9KWh | 14 KWh | 18KWh | 24 KWh |

| Belt width | 400 mm | 500 mm | 500 mm | 500 mm |

| Microwave Zone size in mm (Approx.) | 1800 x 560 x410 (L*W*H) | 2500 x 700 x410 (L*W*H) | 3000 x 700 x410 (L*W*H) | 4000 x 700 x410 (L*W*H) |

| Overall Dimension in mm (Approx.) | 3800 x 720 x 1400 (L*W*H) | 4500 x 720 x 1400 (L*W*H) | 5000 x 720 x 1400 (L*W*H) | 6000 x 720 x 1400 (L*W*H) |

| Preheating Time | 30 minutes | 30 minutes | 30 minutes | 30 minutes |

| Max Preheating temperature | 50° – 70 ̊ centigrade (adjustable) | |||

| MOC | Cavity SS 304/ support structure MS Powder coated | |||

| Standard Models : MW-preheating of Natural Rubber Bale / Master Batch Type | ||||

| Model No: | TW/MWPH/6K/Batch | TW/MWPH/9K/Batch | TW/MWPH/12K/Batch | |

| Production capacity kg /Hr. (approx.) | 80-100 kg/Hrs. | 120-140 kg/Hr. | 170-200 kg/Hr. | |

| Frequency | 2.45 GHz | |||

| Installed Microwave Power requirements | 6 KW | 9 KW | 12 KW | |

| Installed electrical power | 9KWh | 14 KWh | 18KWh | |

| Chamber Dimensions in mm (Approx.) | 800 X 800 X 500 (L *W*H) | 850 X 850 X 750 (L *W*H) | 900X 900 X 950 (L *W*H) | |

| Turn table | 600 mm | 700 mm | 700 mm | |

| Preheating Time rubber Bell | 30 minutes | 30 minutes | 30 minutes | |

| Preheating time for Master Batch | 20 minutes | 20 minutes | 20 minutes | |

| Max Preheating temperature | 50° – 70 ̊ centigrade (adjustable) | |||

| MOC | Cavity SS 304/ support structure MS Powder coated | |||

| Standard Models: batch Type Mw- Preheating of Preform compounds before molding. | ||||||

| TW/BATCH/300/1000 | TW/BATCH/400/2000 | TW/BATCH/500/3000 | TW/BATCH/600/6000 | TW/BATCH/700/9000 | ||

| Production capacity | Kg/Batch | 0.4 – 1.0 | 1.0 -2.0 | 2.0 -5.0 | 5.0 -10 | 10.0 -20.0 |

| Frequency | GHz | 2.45 | 2.45 | 2.45 | 2.45 | 2.45 |

| Installed electrical power | KWh | 1.5KWh | 3.0KWh | 4.5KWh | 9.0KWh | 14.0 KWh |

| Turn table Dia. | mm | 300mm | 400mm | 500mm | 600mm | 700 mm |

| Chamber size: (D*W*H) Approx | mm | 400 x 400 x 275 | 500 X 500 X 300 | 600 X 600 X 400 | 800 X 800 X 500 | 900 X 900 X 750 |

| Voltage | V | 230V AC 1 PH | 230 VAC 1 PH | 415 VAC 3 PH +N | 415 VAC 3 PH +N | 415 VAC 3 PH +N |

| Mechanical Dim(D*W*H) MM (Approx) | mm | 800 x 600 x 700 | 950 x 675 x 950 | 1100 x 840 x 1100 | 1150 X 1300 x 1250 | 1350 x 1450 x 1500 |

| Batch time | 2 to 3 min | 3 to 5 min | 3 to 5 min | 5 to 10 min | 5 to 10 min | |

| MOC | SS304 | Cavity SS 304/ support structure MS Powder coated | ||||

Microwave Preheater Machine Suppliers

Looking for a microwave preheater machine suppliers in India, Bangladesh, Malaysia, Kuwait, Abu Dhabi, Dubai, Sharjah, Ajman, Umm Al-Quwain, Fujairah, Saudi Arabia and Egypt? If so, you came to the right place. For more information on our products and services, please contact our team of experts. We are dedicated to providing you with the best solution for your specific needs.