Microwave Preheater for Tyre

Before molding and vulcanizing the tyre, it is essential for GREEN TYRE to be preheated to certain temperatures. The preheating process easily raises the temperature from room temperature to 60 to 80 °C. Thus, ultimately reducing the molding time for the tyres.

The rubber compounds used for making tyres possess the ability to absorb electromagnetic waves efficiently. Hence, using a microwave for preheating enables faster heating as well as uniform heating from the core to the outer end of the treads. The size of the tyre also plays a vital role in the efficiency of heating. Conventional heating methods take time to penetrate and hence cause differences in the heating patterns.

- MICROWAVE heating acts instantly on a molecular level and heats the material uniformly throughout its volume

- The production time reduces by 50% as the microwave preheater takes care of the heating process.

- The installation space is also considerably lesser in comparison with conventional hot rooms.

- Since the Preheating rate of microwaves is faster than that of the molding press, one Microwave Preheating unit can also serve several molding presses and thus increase production by 30% to 40%.

- Microwave heating is an extremely viable technology for thick treaded tyres as well.

Where does it fit in your chain?

Videos

Microwave Preheater for Tyre

Microwave Preheater for Tyre

MICROWAVE PREHEATER FOR RUBBER TYRE

Let the technology work for you

Advantages:

- Uniform Curing

- Reduce Scrap

- Lower Tooling Cost

- Provide Better Flow

- Reduce Processing Cost

“TWIN” Microwave Preheating system is cost effective solution for Rubber Industries.

Preheating increases Green Strength which is useful when the Tyre components are assembled before vulcanization. The Preheat time is very short in minutes as compared to long time required to cure these thick Tyres.

Depending upon the thickness of the product, Microwave energy can heat rubber up to a hundred times faster than with conventional heating methods.

The technology is GREEN TECHNOLOGY. Saves fuel/electricity, time & also help to reduce environment pollutions.

We also manufacture Microwave Dryers for Pharmaceutical, Rubber, Textile applications & Industrial Microwave Lab Ovens.

Specification:

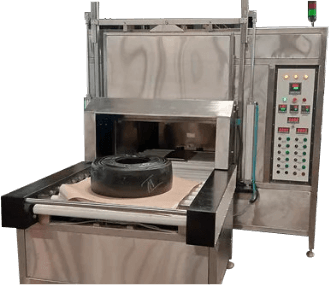

| Batch type Microwave Preheater with Roller conveyor. | |

|---|---|

| Model No: | TW/BATCH/620/5000 |

| Production capacity | 48 KG /Batch |

| Microwave Frequency | 2.45 GHz |

| Installed Microwave Power requirements | 12.0 KW |

| Installed electrical power | 15 KWh (Three phase 4 wire) |

| Turn table size | Suitable for 550mm dia. Tyre |

| Material loading | Automatic on turn table from conveyer. |

| Chamber size | 1000 mm* 1000 mm* 1000 mm |

| Overall mechanical dimensions (LXWXH) | 3200 mm(L) X 1800 mm (W) X 2200 mm(H) |

| Batch time | 15 minutes |

| Preheating temperature | 75 to 90 deg. |

| On line surface temp. Measurement. | Yes |

| Auto door opening on cycle completion | yes |

| MOC | Cavity SS 304 / support structure MS Powder coated. |

Note : Customized Models for higher capacity are also can be made available on request.

Microwave Preheater for Rubber Tyre Suppliers

We specialize in microwave preheaters for rubber tyre suppliers in India, Bangladesh, Malaysia, Kuwait, Abu Dhabi, Dubai, Sharjah, Ajman, Umm Al-Quwain, Fujairah, Saudi Arabia and Egypt. Contact us for more details.